Industry Leading Additive Manufacturing Finite Element Software

Industry Leading Additive Manufacturing Finite Element Software

PanX is licensed as an annual subscription, installed locally on premise.

The only simulation tool on the market capable of accurately scaling to the size and complexity of modern LPBF parts.

The only simulation tool on the market capable of simulating part-scale DED parts. Also offers moving-source simulations several orders of magnitude faster than any other FEA tool on the market.

PanX LPBF

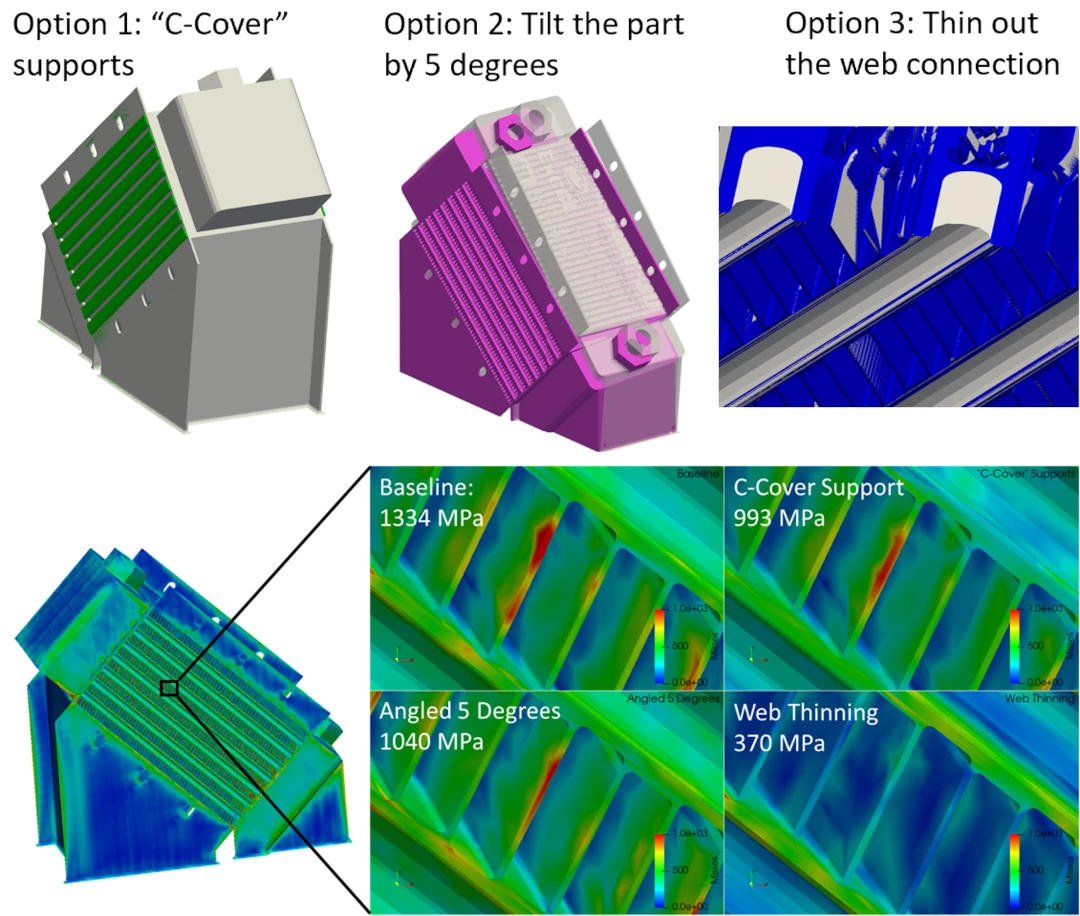

Evaluate Designs

Other FEA solvers would not be able to solve a geometry of this complexity. PanX achieves accurate results substantially faster than the time to manufacture the part.

– Build (print) time: 160hrs

– Part Height: 202mm

– PanX Runtime: 14 hrs. (48 cores)

– Memory Required: 206GB

– Nodes: 54.8 million

– Elements: 25.8 million

– Build (print) time: 160hrs

– Part Height: 202mm

– PanX Runtime: 14 hrs. (48 cores)

– Memory Required: 206GB

– Nodes: 54.8 million

– Elements: 25.8 million

Study based on Penn State ARL paper – Full paper available here

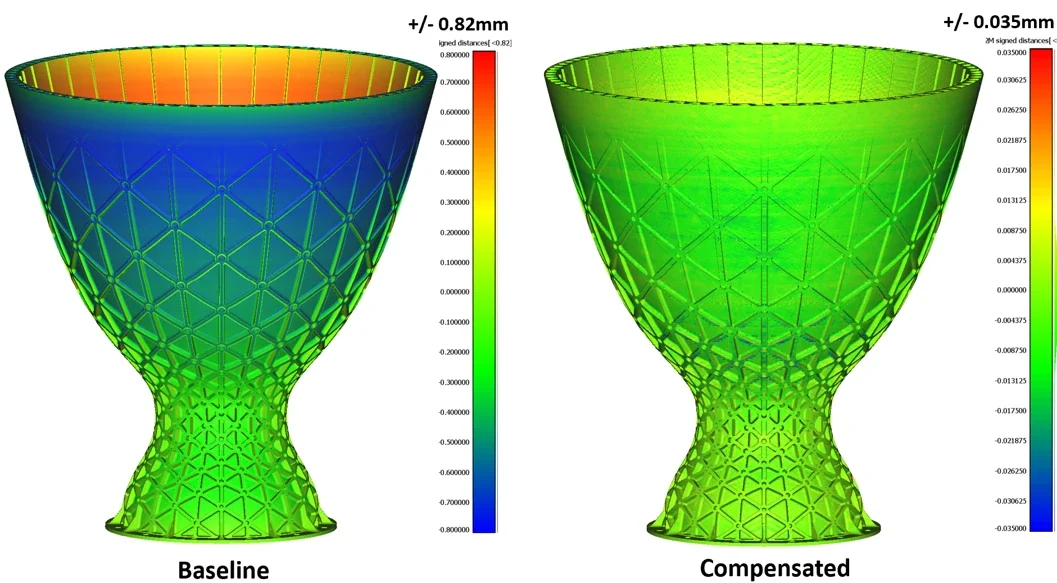

Compensate for Distortion

Because PanX can predict distortion with unprecidented accuracy, it can also apply distortion compensation (pre-deformation) to meet extremely tight tolerances. Here 95% of distortion is removed.

– Part Height: 200mm

– PanX Runtime: 1 hr. 20 min. (48 cores)

– Memory Required: 36GB

– Nodes: 3.5 million

– Elements: 1.5 million

– Part Height: 200mm

– PanX Runtime: 1 hr. 20 min. (48 cores)

– Memory Required: 36GB

– Nodes: 3.5 million

– Elements: 1.5 million

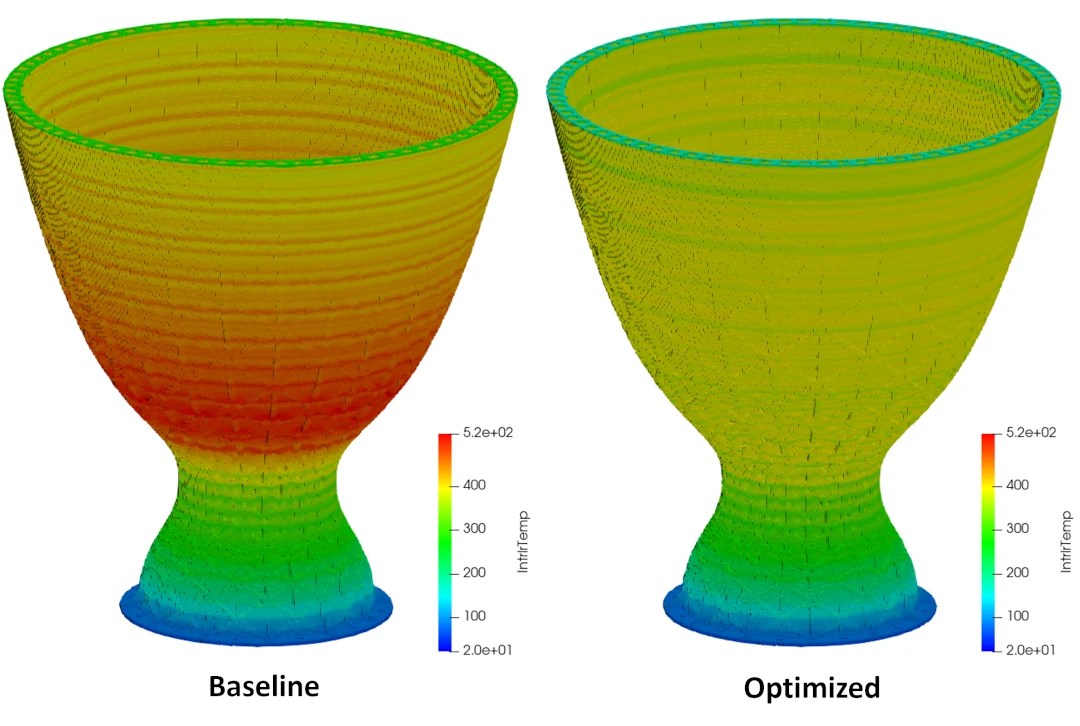

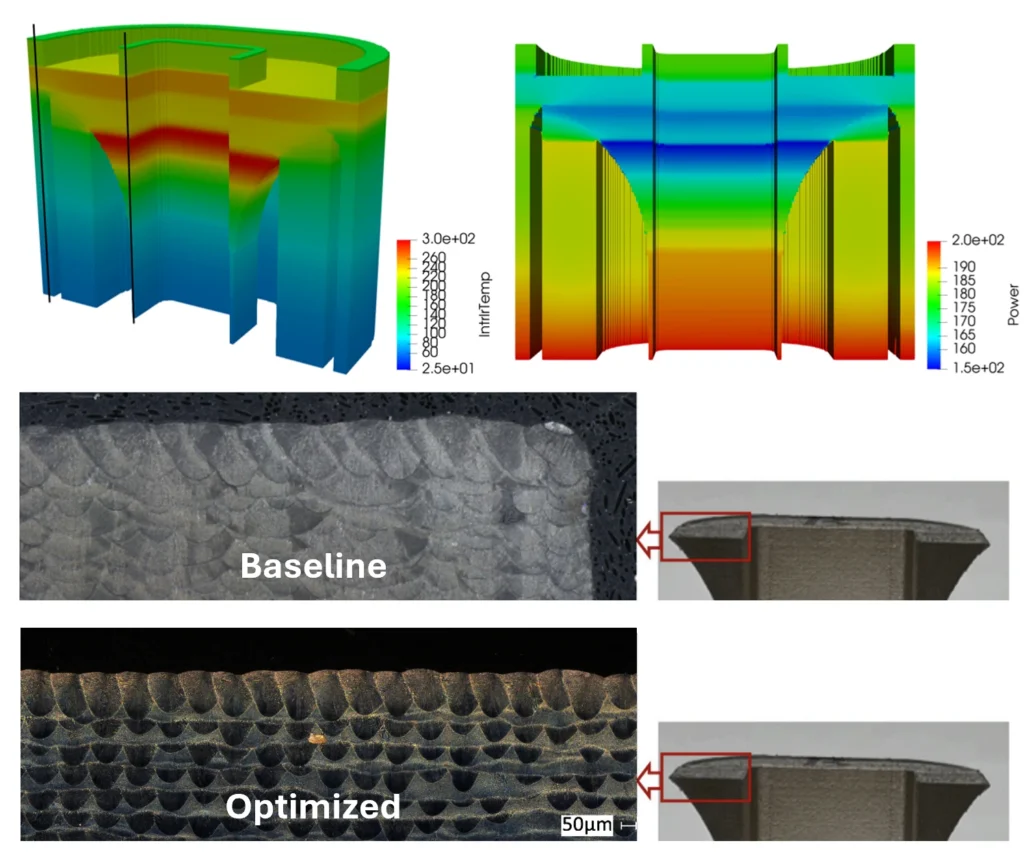

Optimize Dwell Times

PanX can optimize wait (dwell) times between layers to achieve acceptable interlayer temperatures, avoiding issues with overheating.

– Part height: 200 mm

– PanX runtime: 44 min. (48 cores)

– Memory required: 16 GB

– Nodes: 3.5M

– Elements: 1.6M

PanX uses a novel weighted-average thermal modeling approach, capable of achieving extremely high accuracy interlayer temperatures results.

– Part height: 200 mm

– PanX runtime: 44 min. (48 cores)

– Memory required: 16 GB

– Nodes: 3.5M

– Elements: 1.6M

PanX uses a novel weighted-average thermal modeling approach, capable of achieving extremely high accuracy interlayer temperatures results.

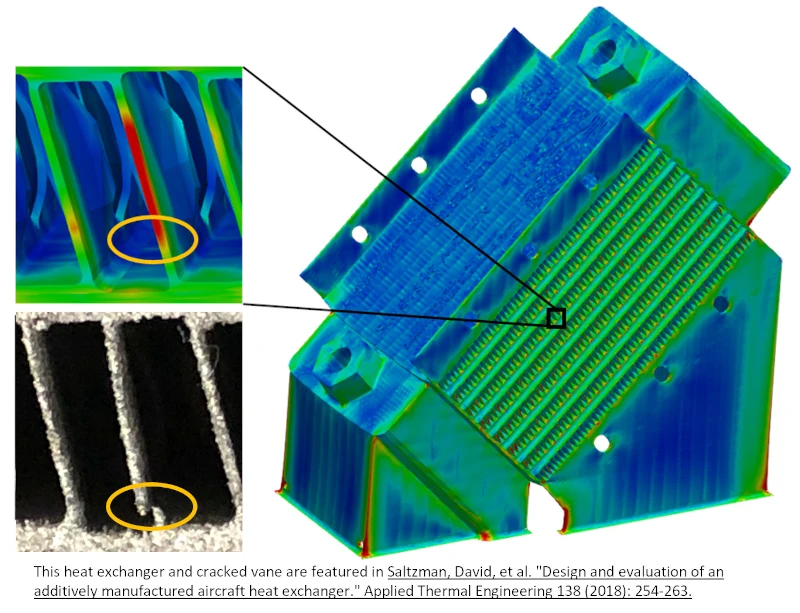

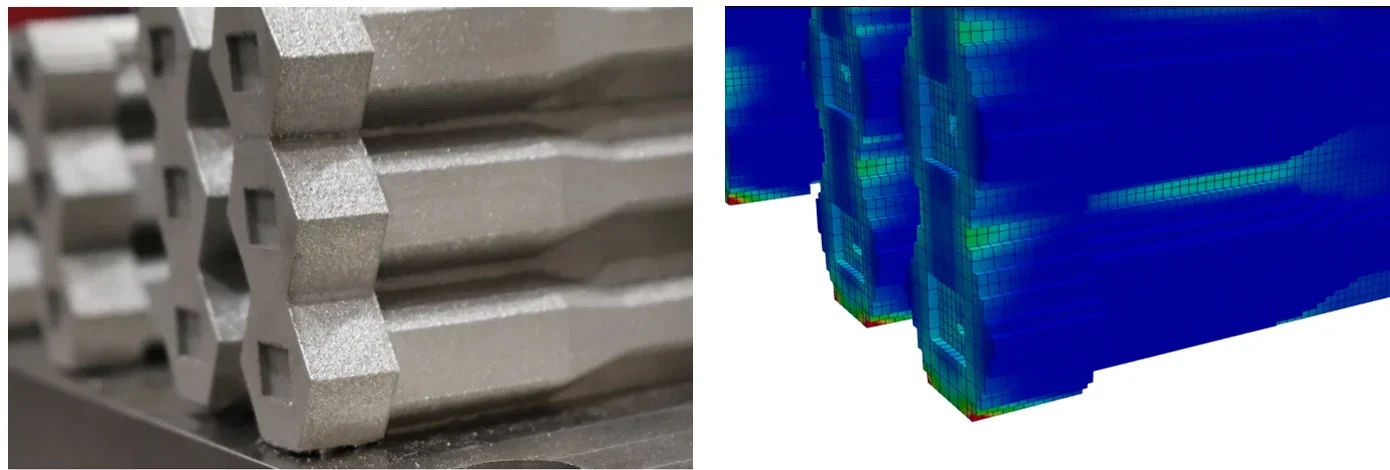

Predict Cracking

PanX uses a novel P-integral approach to eliminate singularities and provide a mesh-independent cracking criterion.

Here the P-Integral indicates high cracking risk.

Here the P-Integral indicates high cracking risk.

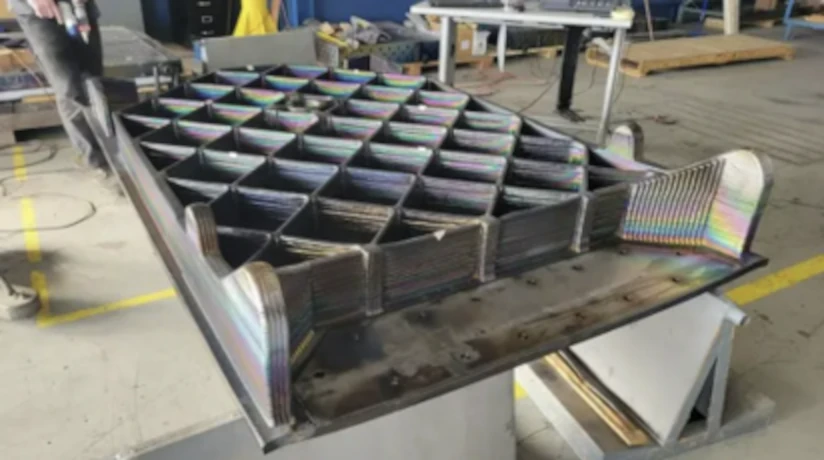

Predict Shrink Lines

Heat exchanger shrink line prediction from PanX. The simulation contained 41.5 million nodes and solves in 11.5 hours on a 48 core desktop machine.

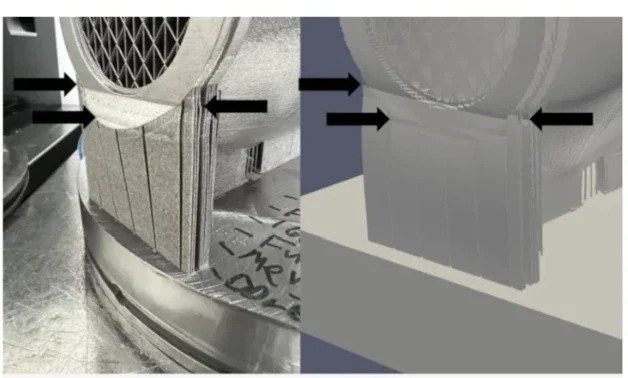

Simulate Parts of Any Size and Complexity

PanX can simulate parts of any size and complexity without needing to homogenize or de-feature the part. This example contains ~570M nodes, making it nearly 100 times larger than anything that could be computed using another FEA package.

Optimize Process Parameters

PanX is an FEA platform that allows users to predict and improve build outcomes virtually, eliminating failed builds that result from experimental trial and error.

We have developed a large set of key technology that overcomes the issues facing traditional FEA tools and enables accurate, scalable, fast, and efficient simulation

We have developed a large set of key technology that overcomes the issues facing traditional FEA tools and enables accurate, scalable, fast, and efficient simulation

Full presentation given at RAPID+TCT 2024.

PanX DED

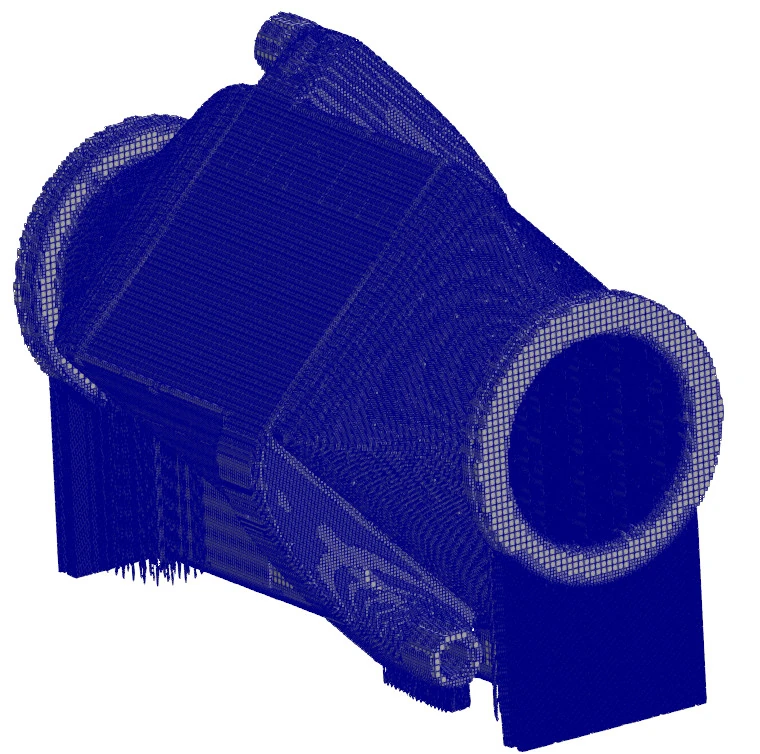

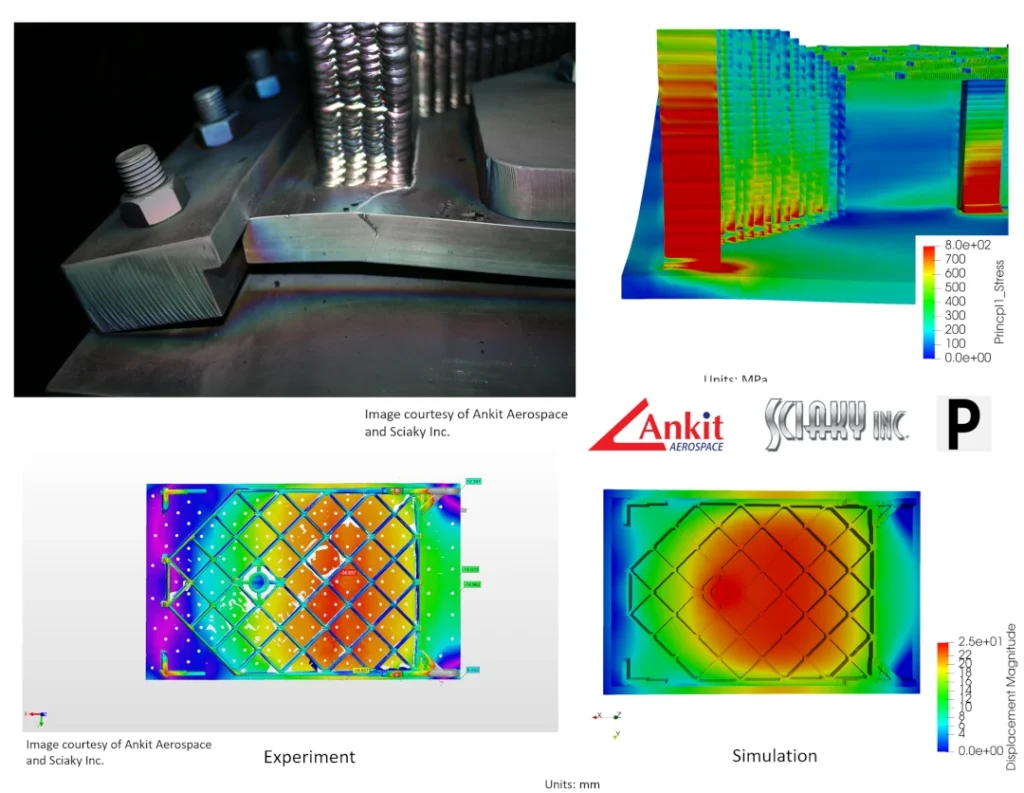

Evaluate Designs, Fixturing, and Toolpath Strategy

PanX DED can quickly simulate meter-class components to assess fixturing, distortion, and stress.

– Part Length: 2.65 meters

– PanX Runtime: 11 min (8 cores)

– Memory Required: 14GB

– Part Length: 2.65 meters

– PanX Runtime: 11 min (8 cores)

– Memory Required: 14GB

Full presentation available here.

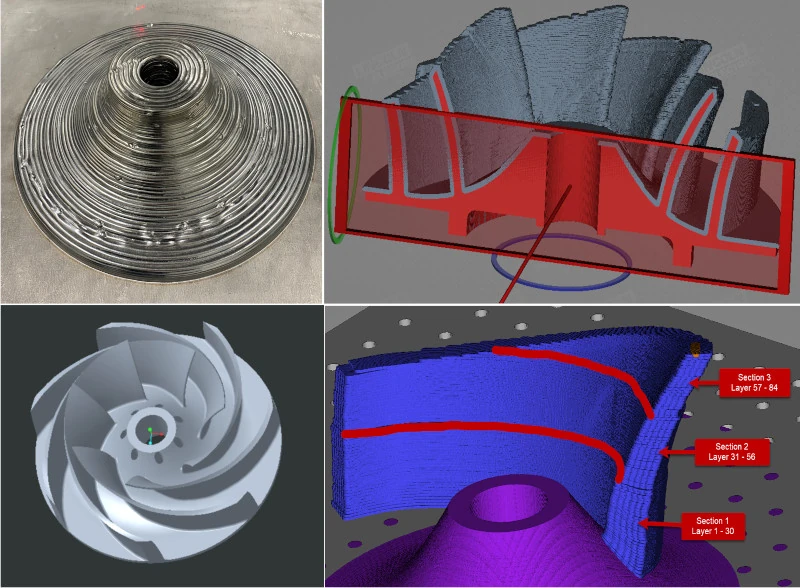

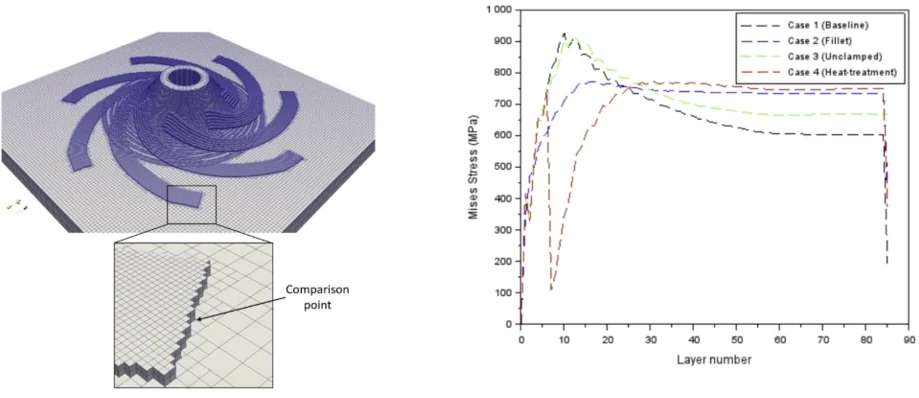

Predict Cracking

PanX can mesh and solve DED builds even for non-planer deposition (6-12 axis deposition) atop arbitrary starting geometries.

In this study of an 800mm x 800mm impeller deposition, PanX was used to investigate the effect of different designs and fixturing strategies on the stress level at the interface of the impeller vanes and the substrate.

The mechanical analysis solves in 1 minute and 34 seconds on a 48-core engineering desktop and requires just 6GB of RAM.

The mechanical analysis solves in 1 minute and 34 seconds on a 48-core engineering desktop and requires just 6GB of RAM.

Excerpt from TechConnect 2023 – Full presentation available here

Simulate 6-Axis Deposition and Cladding

Cladding Example

– Part Height: 1 meter

– PanX Runtime: 4hrs. 8 minutes.

– Memory Required: 50.9GB

– Nodes: 5.4 million

– Elements: 3.3 million

– Part Height: 1 meter

– PanX Runtime: 4hrs. 8 minutes.

– Memory Required: 50.9GB

– Nodes: 5.4 million

– Elements: 3.3 million

6-Axis Deposition Example

– Part Diameter: 1 meter

– PanX Runtime: 48 minutes.

– Memory Required: 25.5GB

– Nodes: 3.0 million

– Elements: 2.1 million

– Part Diameter: 1 meter

– PanX Runtime: 48 minutes.

– Memory Required: 25.5GB

– Nodes: 3.0 million

– Elements: 2.1 million

Optimize Inter-Pass Dwell Times

PanX uses feedforward optimization to compute dwell times needed to achieve target inter-pass temperature for DED deposition.

PanX Product Packaging

PanX+

Full set of PanOptimization products as well as experimental features and future products

- PanX LPBF Thermal Solver

- PanX LPBF Mechanical Solver

- PanX DED Solver

- PanX Dwell Optimization

- Unlimited Problem Size

- Feature Preview

PanXLPBF

Full set of PanOptimization LPBF products

- PanX LPBF Thermal Solver

- PanX LPBF Mechanical Solver

- PanX DED Solver

- PanX Dwell Optimization

- Unlimited Problem Size

- Feature Preview

PanXDED

Products related to Directed Energy Deposition

- PanX LPBF Thermal Solver

- PanX LPBF Mechanical Solver

- PanX DED

- PanX Dwell Optimization

- Unlimited Problem Size

- Feature Preview

PanXTD

Products related to Thermal Dwell Optimization

- PanX LPBF Thermal Solver

- PanX LPBF Mechanical Solver

- PanX DED

- PanX Dwell Optimization

- Unlimited Problem Size

- Feature Preview

PanX16

LPBF solver, but with problem size limited to 16GB of RAM. Intended for small business and educational use

- PanX LPBF Thermal Solver

- PanX LPBF Mechanical Solver

- PanX DED Solver

- PanX Dwell Optimization

- Unlimited Problem Size (Limited to 16GB)

- Feature Preview

Quotes Available by Request at info@panoptimization.com